How ISOBAR® Works

The only true custom-fit compression wear.

ISOBAR® Custom-fit Compression Wear

If compression wear doesn’t fit properly, it doesn’t work—period. That’s why ISOBAR® is made differently.

At ISOBAR, we believe great compression starts with a perfect fit. That’s why we use advanced 3D scanning technology to create a precise digital model of your leg, capturing every curve and contour. Unlike off-the-shelf compression, ISOBAR is built around you, ensuring a flawless fit that delivers maximum comfort, circulation, and performance. We’re the only brand using 3D imaging for true custom-fit compression, redefining what’s possible in performance, recovery, and medical support.

Precision 3D Video Scan

Every ISOBAR sock starts with your leg, your shape, your data. Using advanced 3D imaging, we create a digital wireframe of your leg, capturing every contour for a perfect fit.

- No two legs are the same – So why settle for a generic size?

- 100% Custom Fit – Designed from your scan, not a standard template.

- Unmatched Accuracy – Captures every detail to ensure true medical-grade precision.

Clinically Proven Pressure Profiling

Unlike standard compression socks, ISOBAR applies scientifically tested pressure mapping based on your unique leg profile. Our vascular experts have designed a precision pressure profile that optimises circulation, recovery, and comfort.

- Designed by medical specialists – Built on vascular science, not guesswork.

- Targeted Compression – The right pressure, at the right points, for maximum results.

- Unrivalled Comfort – Custom pressure zones that feel as good as they perform.

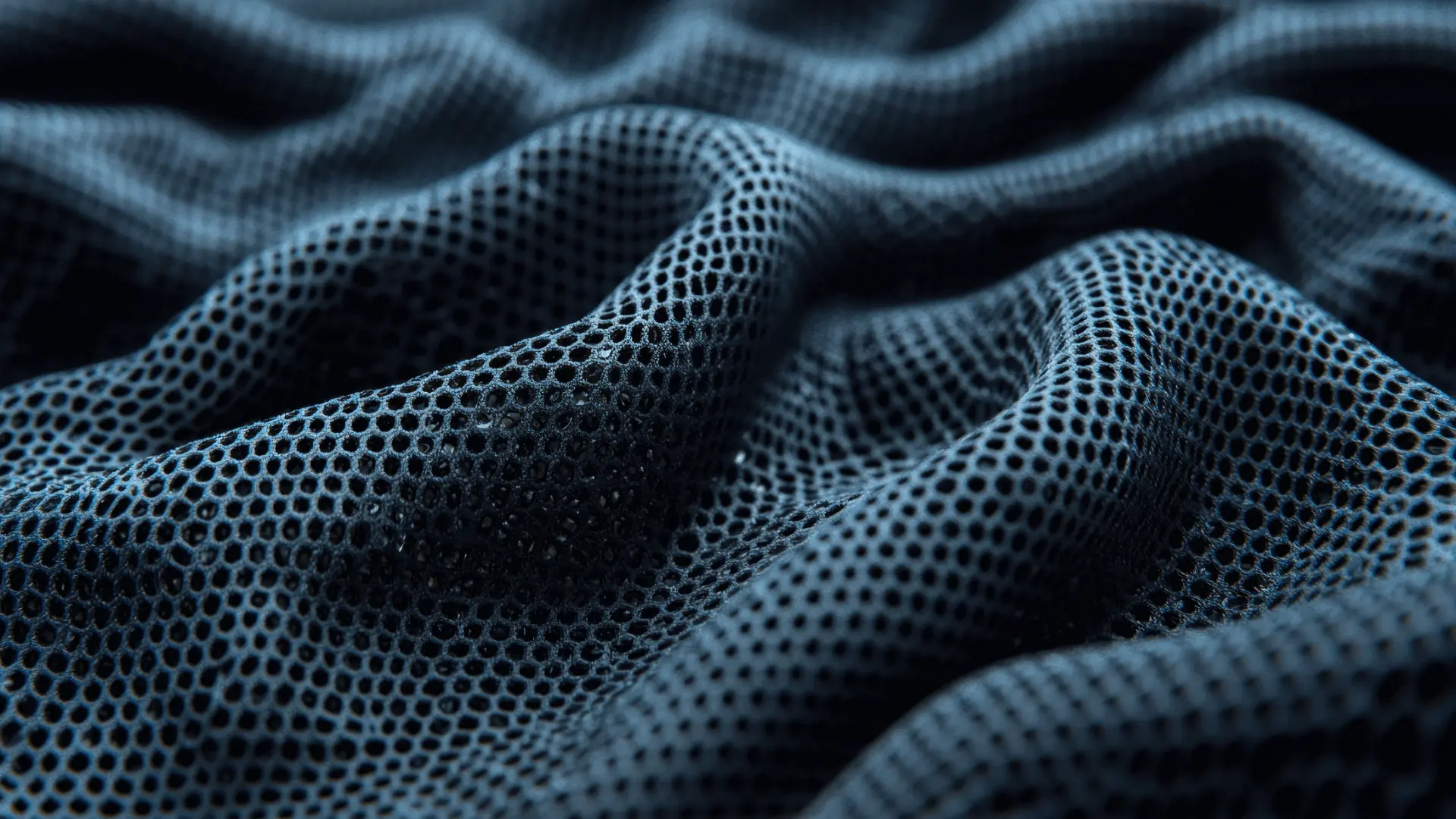

Precision Engineering & On-Demand Manufacturing

Once your scan and pressure profile are set, we use patented knitting technology to create a sock engineered specifically for you. No mass production. No generic sizing. Just pure, precision-fit compression.

- Patented Manufacturing Process – Custom-built for medical accuracy.

- Targeted Compression – The right pressure, at the right points, for maximum results.

- Unrivalled Comfort – Custom pressure zones that feel as good as they perform.

Fast, Direct-to-You Delivery

From scan to delivery, we make the process seamless. Your custom-engineered compression socks are shipped directly to you, ensuring a perfect fit from day one.

- Made-to-order precision – Every pair made uniquely for its wearer.

- Fast & direct – Custom-fit compression, delivered straight to your door.

- Compression that actually works – The only true custom-fit compression wear.